A barcode is a series of optical data that can be read by scan engine printer. This code is regularly gathering data in line and parallel line space often called to be a barcode. UPC barcode is often found on some products of food to specify those products. It is initially used to automate checking system on the supermarket in which it becomes universal right now. An optical scanner reads the barcodes. To know closer about this barcode, here are some interesting secrets.

History of UPC Barcode

A bar code data is systematically represented (black and white vertical lines) by varying the width and spacing of parallel lines to store specific data such as production code, ID number, etc. so that the computer system can quickly identify the information encoded in the barcode. Inside the bar code contains information or data that is usually in the form of numerical data. That number also listed below the barcode.

Why Using Barcode?

If there is already a number why required barcode? The answer is; devices such as computers more quickly to read digital data rather than analog numbers. A barcode with color contrast (black and white) easily recognized by optical sensors CCD (Charge Couple Device) or laser that exist on the scanner (barcode scanner), and then translated by a computer into numbers.

The history of bar code started from a general history of barcode use. In 1923, Wallace Flint made a checking system of products in retail companies. Initially, the barcode technology was controlled by retail businesses and followed by industrial companies to make a reading system of product information in checkout automatically. Then, Bernard Silver and Norman Joseph Woodland, a graduate of Drexel patent application, join forces to find solutions. Woodland proposes ink sensitive to ultraviolet light. The prototype has rejected because it is unstable and expensive. Afterward, October 20, 1949, Woodland and Silver managed to make the prototype better. And, on October 7, 1952, they got a patent on the results of their research. 1966: The first time a barcode is used commercially in 1970 when Logicon Inc. managed to make the Universal Grocery Products Identification Standard (UGPIC).

The first company that produces equipment for the retail barcode is Monarch Marking. Was first used in the industry by Plessey Telecommunications and a Kroger store in Cincinnati started using the bull’s-eye code in 1972. Besides, a committee was formed in the grocery industry to choose standard systems to be used in their industry.

And now, the term of barcode seems to be familiar currently. You almost see this barcode number anywhere especially supermarket. It is related to the barcode of products and items sold in retails and supermarket. One of the popular barcodes in the United States is UPC or Universal Product Code. This bar code is a compliment of black and white vertical printing lines with a different width to keep accurate data including identity number, production code, computer system, and many more to identify it quickly. In UPC barcode that has made on UPC code lookup, there is complete data and information that are usually in number data.

Type of UPC Barcodes

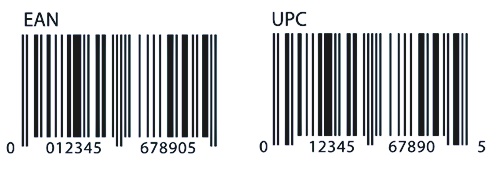

UPC barcodes can be verified on UPC code lookup to be able to detect by optical scanners in the supermarkets. To give you information about this barcode, it consists of two types. UPC bar code is closely similar to EAN code that has used for some products and items. If you look at those systems, you will admit that those look the same. UPC barcodes include UPC-A and UPC-E barcodes. Though there are some differences between them, the most significant difference is the geographic application. UPC codes are applicable in the United States. UPC (Universal Product Code)-A consists of 12 digits in which it is 11 data digits and one check digit for retail industry needs. Meanwhile, UPC-E consists of 7 digits in which it is 6 data digits and one check digit for small scale retail industries. It means that UPC-A is implementing for big retail industries. Otherwise, UPC-E is designed for creating labels for small industry needs. There is also another UPC code in the European version. This version is called the UPC-A Europe version. It is same as EAN-13. It includes 13 digits where it is 12 data digits and 1 check digit. It is allowed using one of those UPC types for your industrial needs.

The Use of UPC Barcode

UPC barcodes have been an important part of modern culture. The use of the barcode has been spread widely making it gets developing. The making of UPC barcode, of course, has some purposes. Almost all products sold in grocery, department stores, and supermarket have used and had UPC barcode. This’s very useful to trace all sold items by showing the price and previous data that has programmed. The use of UPC barcode on retail can identify every item and product bought in the retail. It makes supermarket supervisors able to check and control sold products easily. UPC barcodes are ordinarily utilized for products carried in the supermarket.

The use of UPC barcodes is very easy in which it can keep much money for food industry every year. Even, it surprisingly can gain profits of millions of dollars from maximizing the use of UPC barcodes on UPC code lookup in the retail. Since the UPC scanner produces efficiency and productivity improvement, it causes the cost to below. It’s claimed that there are more than 10.000 companies in the industry in the United States using this barcode and enjoying benefits of this barcode. The barcode can be found not only for food products, but it is also for cosmetic items and constructions. It gets increasing and general for products in retails.

The Determination of Product Information on UPC Barcode

UPC barcodes cannot be separated from items sold in the supermarket. The use of UPC barcode initially aimed at helping a validation process of an object and tracking it quickly. When retails want to use this barcode, it should get legal approval from UCC (Uniform Code Council) handling this barcode. As you see this barcode, there is nothing special. There is no price information of products. But, when a cashier scans it, a cashier machine records and sends the data on UPC barcode to the server. This serves called to be a point of sale in which it is a group of all information needed for an individual product in a supermarket. The information is actual and valid in a real-time sent to cashier machine. This method eases cashiers to change price data anytime.